VIIST is a leading injection molding manufacturer specializing in high-precision plastic parts production for diverse industries. We partner with medical, automotive, consumer electronics, and optical companies to deliver mass-production solutions that combine exceptional quality with cost-effectiveness. Our comprehensive service covers everything from mold design to final assembly.

Our advanced injection molding capabilities ensure:

Process Advantages:

Cost-effective for high-volume production

Excellent repeatability and consistency

High production speed with fast cycle times

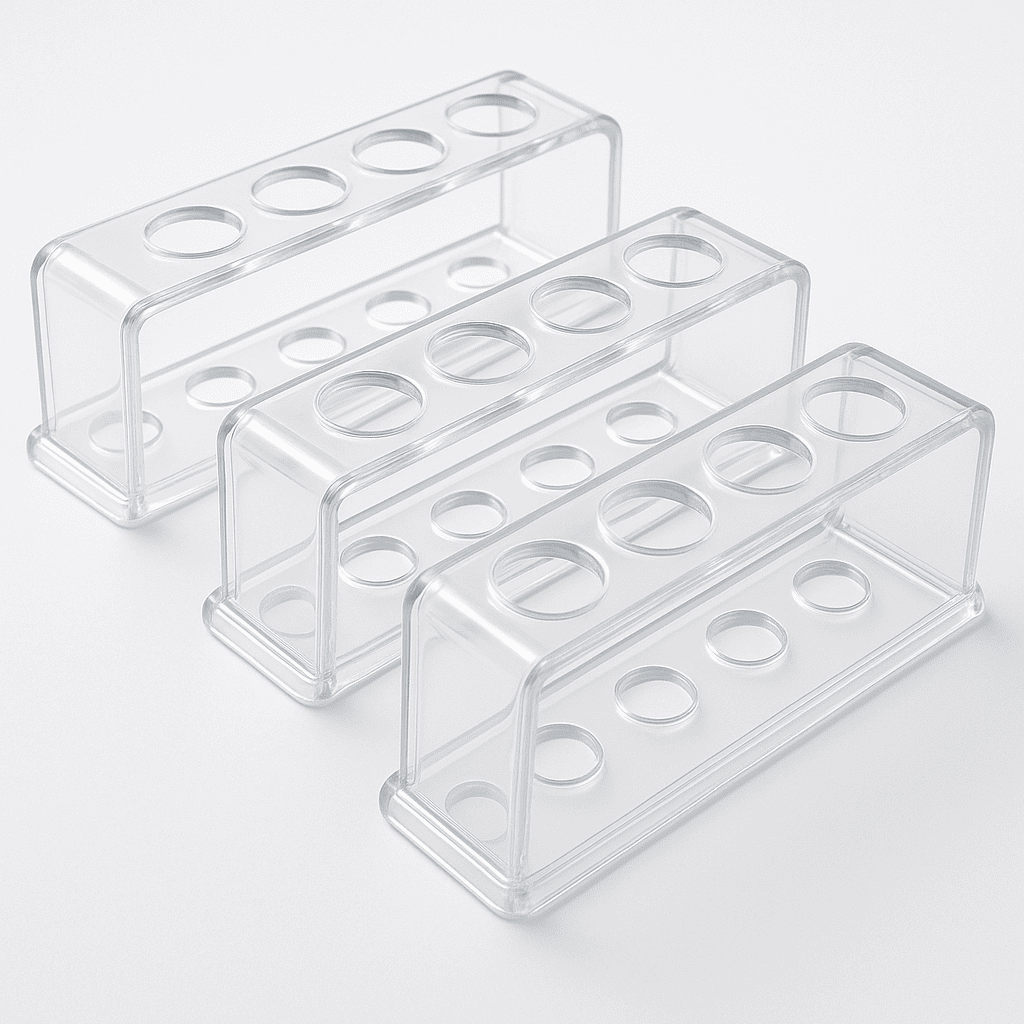

Complex feature integration in single parts

Minimal post-processing requirements

Material Expertise:

Polycarbonate (PC): Impact resistance, optical clarity

Acrylic (PMMA): Excellent transparency, UV stability

ABS: Good mechanical strength, cost-effective

HDPE: Chemical resistance, flexibility

PVC: Versatility, flame retardancy

1. Advanced Equipment Portfolio

20 Injection Molding Machines: 50-500 ton clamping force

Electric Injection Machines: Precision control, energy efficiency

Multi-material Molding: Two-shot and overmolding capabilities

Robotic Automation: Automated part removal and assembly

Cleanroom Molding: Class 1000 environment for optical parts

2. Advanced Equipment Portfolio

| Parameter | Capability | Tolerance |

| Clamping Force | 50 – 500 tons | N/A |

| Shot Weight | 10g – 2000g | ±0.5% |

| Part Size | Up to 500mm × 500mm | ±0.02mm |

| Wall Thickness | 0.5mm – 10mm | ±0.05mm |

| Cycle Time | 15-60 seconds | Consistent |

3. Surface Treatment Expertise

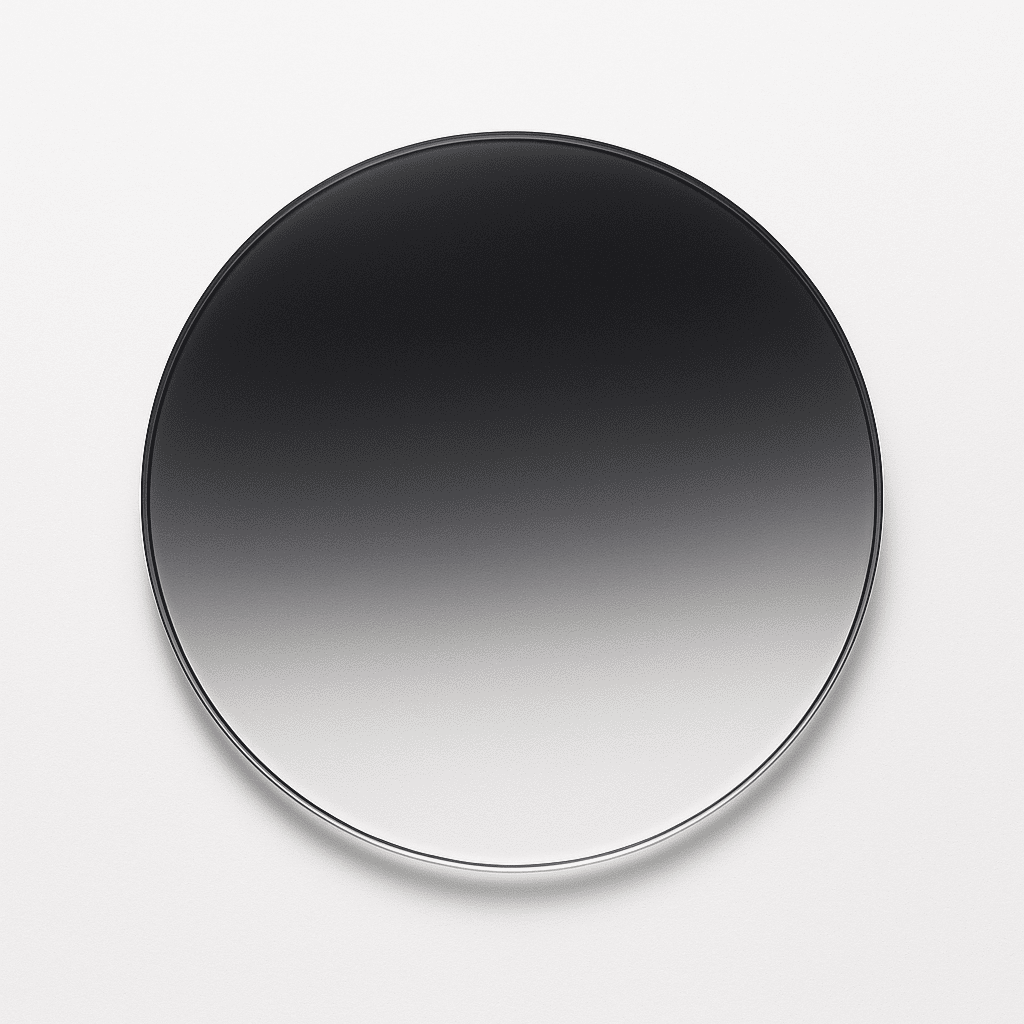

Hard Coating: Up to 9H pencil hardness

Anti-Fog Treatment: Permanent hydrophilic coatings

Anti-Glare (AG): Surface etching for optical diffusion

Anti-Reflective (AR): Multi-layer optical coatings

Anti-Fingerprint (AF): Oleophobic nano-coatings

UV Protection: Coatings for outdoor applications

Texture Painting: Custom surface patterns and finishes

1. Design & Engineering

DFM analysis for manufacturability optimization

Mold flow analysis for filling pattern prediction

Gate and runner design for optimal material flow

Cooling system design for cycle time reduction

2. Mold Making

Precision machining of mold components

Surface treatment of mold cavities

Trial shots and mold validation

Final adjustment and certification

3. Production Molding

Material preparation and drying

Process parameter optimization

Automated production with robotic assistance

In-process quality inspection

4. Post-Processing

Gate removal and trimming

Surface treatment application

Quality inspection and testing

Packaging and shipment preparation