CNC Polycarbonate Machining: Your Complete Guide

Contents:

1. What is CNC Polycarbonate Machining?

1.1 Brief overview of CNC machining

1.2 Machinability of polycarbonate

2. Types of Machining Polycarbonate?

2.1 Milling

2.2 Drilling

2.3 Turning

2.4. Routing

2.5 Engraving and Etching

2.6 Laser Cutting

2.7 Waterjet cutting

3. How to CNC Polycarbonate Machining?

4. Acrylic vs Polycarbonate CNC Machining

5. Expert Tips to Machining Polycarbonate

6. FAQ

1. What is CNC Polycarbonate Machining?

1.1 Brief overview of CNC machining

CNC (Computer Numerical Control) machining polycarbonate refers to the process of shaping, cutting, drilling on polycarbonate material with computer-controlled machining tools. In this process, a CNC machine follows pre-programmed instructions to precisely control the movement of cutting tools, such as drills, mills, routers, or lasers, to achieve the desired shape and dimensions on polycarbonate sheet.

1.2 Machinability of polycarbonate

The machinability of Polycarbonate is exactly due to its excellent properties (high transparent, lightweight and durable, impact resistance etc).Combining with CNC machining service, polycarbonate sheets are widely applied various applications including aerospace, automotive, electronics, signage, and consumer goods etc.

2. Types of CNC Machining Polycarbonate?

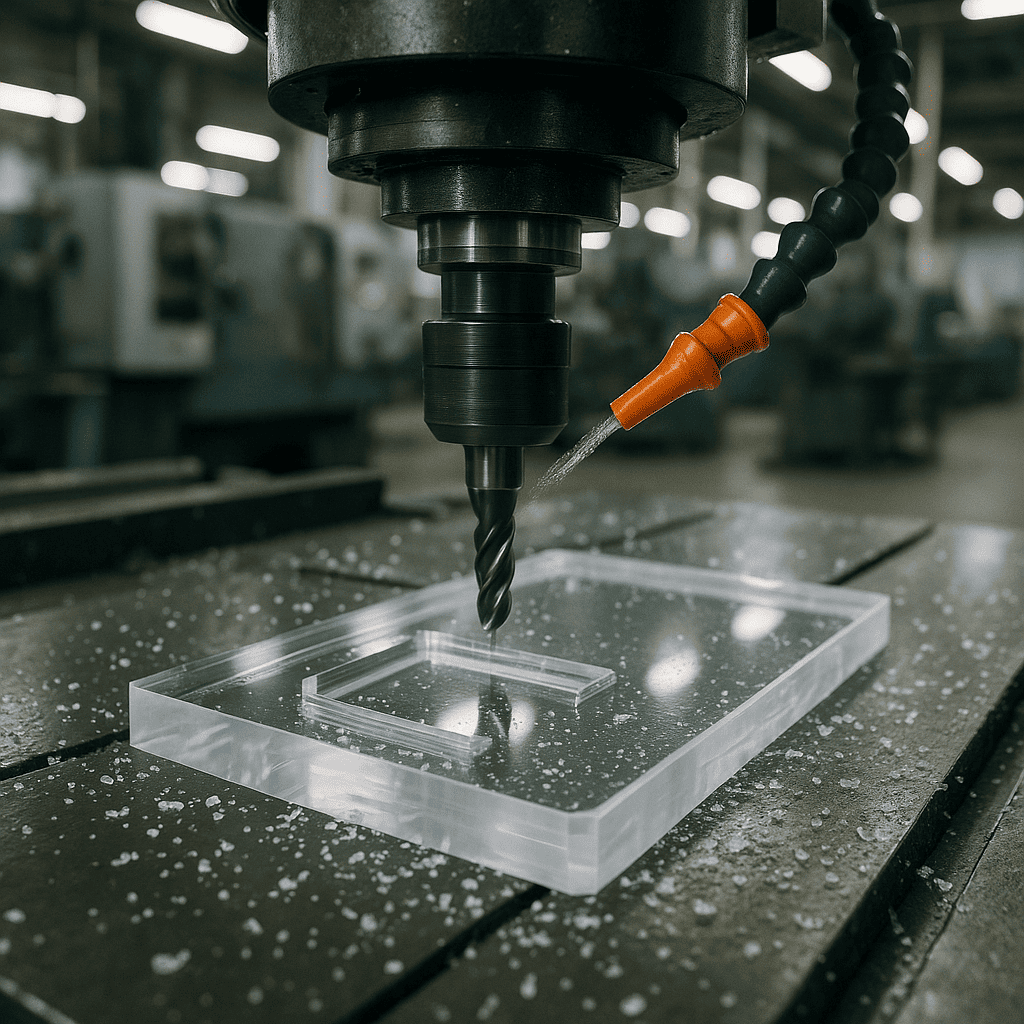

2.1 CNC Milling

Polycarbonate milling includes face milling, contour milling, pocket milling, and slot milling. By removing material from a polycarbonate workpiece to achieve the desired shape, dimensions, and surface finish.

2.2 CNC Drilling

Drilling is very common in polycarbonate CNC machining , it involves creating holes or openings in polycarbonate material using drilling tools.

2.3 Turning

CNC polycarbonate turning is a machining process by rotating a polycarbonate workpiece while a cutting tool removes material to achieve the desired shape, dimensions, and surface finish.

2.4 Routing

CNC routing is widely used in plastic fabrication including cut, carve, or shape. It is suitable for creating 2D and 3D shapes, complex designs, and custom parts.

2.5 Engraving and Etching

Polycarbonate Engraving mainly used to create designs, patterns, or text on the surface of the polycarbonate workpiece by using a laser or rotary tool.

2.6 Laser cutting

It is a kind of CNC cutting method by melting, burning, or vaporizing the material with a high-powered laser beam.

2.7 Waterjet Cutting

Different from the laser cutting,waterjet cutting utilizes a high-pressure stream of water mixed with abrasive particles to cut through materials by erosion. There will be no heat-affected zones or mechanical stress during the process.

3.How to CNC Polycarbonate Machining?

Here’s a detailed guide on how to machining polycarbonate accurately and efficiently on CNC Machines.

Step 1. Preparing CAD Drawing first

Getting the digital model that includes all necessary dimensions, features, and specifications from your customers or engineers.

Step 2. CAM Programming

Import the CAD model into CAM software to generate toolpaths of cutting operations. Setting cutting tools, cutting speeds, feeds, and depths for each operation.

Step 3. Material Setup

Fix the polycarbonate sheet well on the machine’s worktable by using clamps, vacuum hold-downs, or other fixtures.

Step 4. Tool Selection and Setup

Choose appropriate cutting tools. You need to know well about the CAM program and the properties of polycarbonate material. The end mills, drills, and routers are common tools for polycarbonate machining.

Step 5. Machine Setup

You need to set up the CNC machine according to the requirements of the CAM program. For example, loading the CNC program into the machine’s control unit, setting the workpiece origin (zero point), and configuring cutting parameters such as spindle speed, feed rate, and tool offsets.

Step 6. Cutting Operations

Execute the CNC program, to start the machining operations defined in the CAM software.

Step 7. Coolant and Chip Management

To prevent overheating of the cutting tools and workpiece by using coolant or lubricant.

Step.9. Finishing Operations

After machining,some finishing operations are needed including deburring, sanding, polishing, or coating the machined surfaces as required.

Step.10. Final Inspection and Testing

To do some tests or quality checks as necessary to verify the functionality and performance of the machined polycarbonate components.

By following above steps systematically and accurately, you can machine polycarbonate material to create precise, high-quality parts and components for various applications. Of course, you need qualified with professional knowledges about polycarbonate material and special skills about the operation of CNC machines. VIIST with professional R&D and engineers team who are more than 10 years experience in CNC machining, just contact us, we will provide you one-stop service from design to choosing the right polycarbonate material to setting up correct cnc machining process to ideal reality products.

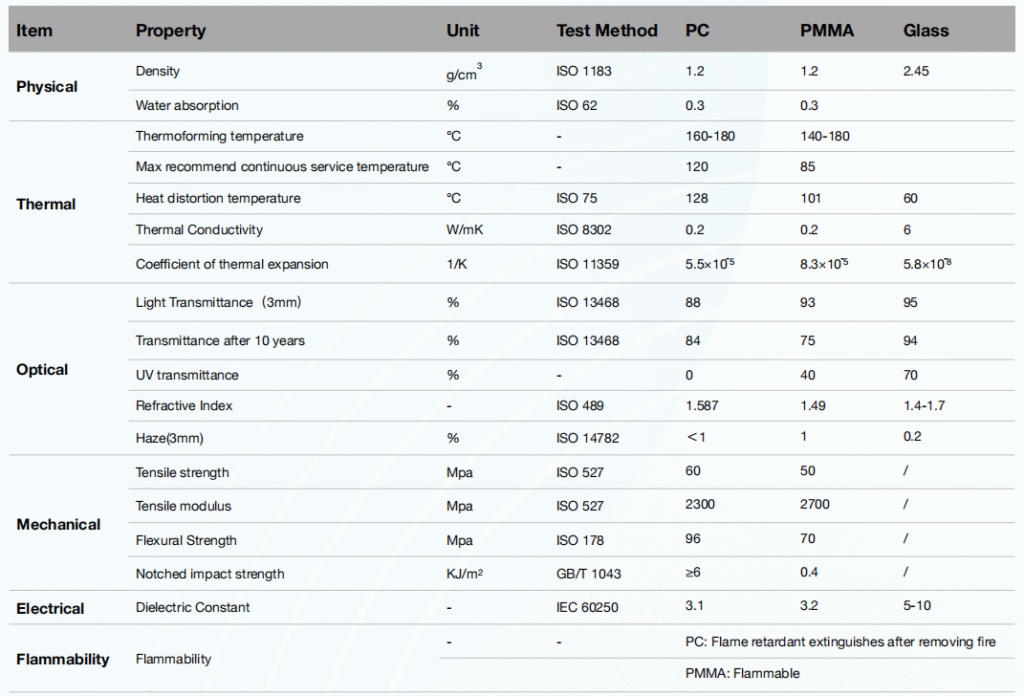

4.Acrylic vs Polycarbonate CNC Machining

Acrylic ( also named PMMA or Plexiglas) and polycarbonate ( also named PC) are two popular thermoplastic materials both are all good glass alternatives. While they share some similarities, such as excellent optical transparency, light weight, and easy to machine, they also possess distinct characteristics that impact their machining processes and applications. In this section, we will compare acrylic CNC machining with polycarbonate CNC machining, highlighting their differences in terms of material properties, machining techniques, applications, and considerations for choosing between the two.

Material Properties:

Acrylic (PMMA):

Acrylic is produced in either cast or extruded form. Cast acrylic is more suitable for machining, due to its higher melting point and rigidity makes it more stable during the machining process to meet stricter tolerances. Extruded acrylic is more flexible and better suited for bending or forming operations.

Transparent, with excellent optical clarity up to 93% light transmittance similar to glass.

Lower Toughness, Brittle compared to polycarbonate, prone to cracking and chipping.

Resistant to UV radiation and weathering.Unlike PVC or unmodified polycarbonate, acrylic does not yellow over time when exposed to UV light, but instead maintains its optical transparency.

Scratch Sensitive, easy scratched, anti-scratch coating often applied on the surface of the acrylic panel depends on the application request.

Polycarbonate (PC):

Due to its toughness and impact resistance, polycarbonate is favored in some applications which requires robust components, such as helmet visor, safety equipment, protective covers, machine guards, and automotive parts. CNC-machined polycarbonate parts are commonly found in aerospace, medical devices, and industrial machinery.

Transparent, with good optical clarity 88% light transmittance and impact resistance.

Good toughness, highly durable and tough, with excellent impact strength, less prone to cracking or breaking compared to acrylic.

Resistant to UV radiation, polycarbonate itself is poor UV resistant, normally, especially for outdoor application,during the extrusion production process, some UV stabilizer additives will be added to prevent yellowing.

Scratch Sensitive, the polycarbonate sheet is poor scratch resistant, but this can be solved by combining with the hard coating ( anti-scratch coating) dealt with on the surface.

| Aspect | Acrylic CNC Machining | Polycarbonate CNC Machining |

| Material Properties | Exceptional optical clarity and UV resistance. | Superior impact resistance and toughness. |

| Relatively low melting point, facilitating machining. | Higher melting point requires careful parameters. | |

| Brittle nature, prone to cracking under high stress. | More flexible, less prone to shattering. | |

| Machining Techniques | High-speed cutting with sharp tools. | Lower cutting speeds and feeds to control heat. |

| Responds well to machining, allowing fast removal. | Specialized tooling required for heat resistance. | |

| Careful chip evacuation to prevent surface defects. | Attention to chip formation and evacuation. | |

| Applications | Signage, displays, architectural components. | Safety equipment, protective covers, machine guards. |

| Decorative fixtures, lenses, light diffusers. | Automotive components, aerospace applications. | |

| Considerations | Optical clarity, aesthetic appeal. | Impact resistance, durability. |

| Machining complexity, surface finishes. | Environmental factors, operating conditions. | |

| Cost considerations, post-processing requirements. | Cost-effectiveness, material longevity. |

Performance Comparison Table Acrylic vs Polycarbonate

5.Expert Tips to Machining Polycarbonate

- Understanding Polycarbonate:

Before diving into machining techniques, the first things is to understand the properties of polycarbonate. Polycarbonate is known for its exceptional strength, transparency, and resistance to impact. However, it can be prone to chipping, melting, or cracking if not machined properly. Being aware of these characteristics will guide your approach to machining. Go to our website viistoptical.com to learn more about polycarbonate.

- Choosing the Right Tools:

Selecting the appropriate tools is crucial for successful machining of polycarbonate. Carbide-tipped tools are recommended for cutting and drilling polycarbonate due to their hardness and durability. High-speed steel (HSS) tools can also be used but may require slower speeds and more frequent tool changes.

- Optimizing Cutting Speeds and Feeds

Choose the correct cutting speeds and feeds to prevent overheating, and ensure a smooth finish when machining polycarbonate. Generally, lower cutting speeds and feeds are preferred to minimize friction and prevent melting or chipping. Experimenting with different settings and observing the results can help determine the optimal parameters for your specific machining application.

- Cooling and Lubrication

Cooling and lubrication play a critical role in preventing heat buildup during machining. Using a coolant or lubricant specifically designed for polycarbonate can help dissipate heat and improve chip evacuation. The air or mist cooling systems can be effective alternatives for smaller-scale machining operations.

- Minimizing Vibration

Vibration can lead to inaccuracies and surface imperfections when machining polycarbonate. To minimize vibration, ensure that the workpiece is securely clamped to the machine bed and use stable cutting conditions. By using sharp tools with proper geometries can also reduce chatter and vibration during cutting.

- Avoiding Chip Buildup

To maintain a clean and efficient machining process, you need to preventing chip buildup. Employing chip evacuation strategies such as using compressed air or vacuum systems can help remove chips and debris from the cutting area. What’s more, ensuring proper tool geometry and chip breaker designs can aid in chip control and management.

- Finishing Techniques

Achieving a smooth and polished finish is often desired when machining polycarbonate for applications such as optical components or display screens. After rough machining, employing techniques such as buffing, sanding, or flame polishing can help remove tool marks and surface imperfections, resulting in a high-quality finish.

- Safety Precautions

The last and most important thing is safety issues during machining polycarbonate. Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and respiratory protection, to protect against dust, chips, and fumes. It is necessary to ensure proper ventilation in the machining area to minimize exposure to potentially harmful fumes or vapors.

FAQ:

Q:What’s the cutting process for polycarbonate?

A:The cutting process for polycarbonate involves several steps.

First, Security the polycarbonate sheet on the machine bed well.

Second, Choosing the appropriate tool for the job.

Third,Determine the optimal cutting speeds and feeds based on the thickness of the polycarbonate.

Fourth,Apply a suitable coolant or lubricant to the cutting tool and workpiece to dissipate heat and reduce friction during cutting

Final, After cutting, inspect the edges of the polycarbonate sheet for any roughness or burrs

Q: Can I cut polycarbonate sheets with a utility knife?

A: Yes, you can cut polycarbonate sheets with a utility knife, especially thinner sheets (typically up to 1/8 inch or 3mm thick). However, for thicker sheets, it’s recommended to use a saw or specialized cutting tool for better results.

Q:How do you polish polycarbonate after machining?

A: you can polish polycarbonate by using fine-grit sandpaper to smooth out any rough edges or imperfections. Then, apply a plastic polish or a mild abrasive polish in circular motions with a soft cloth to achieve a smooth and glossy finish.

Q:Can you bend polycarbonate without heat?

A: Yes, it’s possible to bend polycarbonate without heat by using a cold bending technique. This involves clamping the polycarbonate sheet along the desired bend line and gradually applying pressure until the sheet bends to the desired angle. However, cold bending is typically suitable for thinner polycarbonate sheets and may not be as effective for thicker or more rigid sheets like coated polycarbonate sheets.

Q: Can polycarbonate be screwed?

A:Yes, polycarbonate can be screwed. Pre-drilling holes slightly larger than the diameter of the screw is recommended to prevent cracking or splitting of the material when inserting screws. Additionally, using screws with large washers can help distribute the pressure evenly and reduce the risk of damage to the polycarbonate surface.

Q:Does polycarbonate shrink when heated?

A:Polycarbonate does not shrink significantly when heated. Instead, it softens and becomes more pliable, allowing it to be molded or formed into different shapes. However, rapid cooling after heating may cause minor dimensional changes, but these are usually minimal compared to other thermoplastics.

Q:How to make polycarbonate clear after machining?

A: You can make polycarbonate clear after machining by sanding, buffing, and polishing the surface

Q: Can we machine coated polycarbonate and coated acrylic sheet?

A:Yes, coated polycarbonate and acrylic sheets can be machined, but caution is needed to avoid damaging the coating during the machining process.

VIIST supports a comprehensive range of CNC machining services is available at our workshop, which is equipped with CNC routers, lathes, 5-axis milling machines, and thermoforming machines.Now contact us to start your project.