VIIST is a specialized plastic CNC machining manufacturer focusing on engineering-grade thermoplastics for precision components. We partner with optical, medical, consumer electronics, and automotive industries to deliver custom plastic parts with exceptional accuracy and superior surface quality. Our expertise covers prototyping to high-volume production of complex plastic components.

Our advanced plastic machining capabilities ensure:

Polycarbonate (PC): Impact-resistant, optical clarity

Acrylic (PMMA): Excellent transparency, UV resistance

ABS: Good mechanical strength, cost-effective

HDPE: Chemical resistance, low moisture absorption

| Material | Application | Surface finish | Tolerance Capability |

| Polycarbonate | Optical covers, protective shields | Excellent | ±0.02mm |

| Acrylic (PMMA) | Display windows, light guides | Optical quality | ±0.03mm |

| ABS | Housings, enclosures | Very good | ±0.05mm |

| HDPE | Chemical containers, wear parts | Good | ±0.08mm |

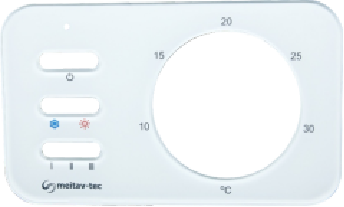

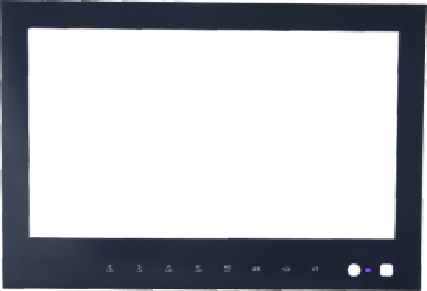

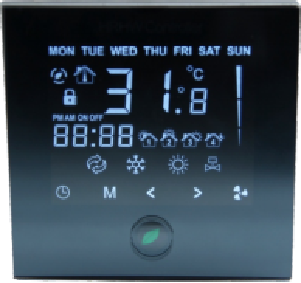

Optical & Display Industry

Medical Devices

Consumer Electronics

Industrial Applications

1. Material Selection & Preparation

Material drying to prevent moisture issues

Stress-relief annealing pre-machining

Grain direction consideration for anisotropic materials

2. Specialized Machining Techniques

High-speed machining: Preventing material melting

Sharp tool geometry: Clean cutting without burrs

Coolant-free machining: Preventing material contamination

Multi-stage machining: Progressive tolerance achievement

3. Post-Machining Processing

Stress relief: Thermal treatment for critical parts

Deburring: Plastic-specific edge finishing

Surface enhancement: Polishing and texturing

Cleaning: Ultrasonic cleaning for optical parts

4. Quality Validation

Dimensional inspection: CMM verification

Surface quality: Visual and instrumental inspection

Functional testing: Assembly and fit verification

Coating performance: Adhesion and durability testing

VIIST offers:

Free Material Consultation: Optimal plastic selection

DFM Analysis: Design for manufacturability review

Rapid Prototyping: 3-5 day lead time

Volume Production: Competitive pricing for large orders

Complete Finishing: Full surface treatment capabilities