VIIST, as a one-stop expert in optical display cover glass processing, understands that materials are the cornerstone of superior performance. Polycarbonate (PC), with its excellent impact resistance, high light transmittance, lightweight, and outstanding processing adaptability, has become the ideal choice for cover glass materials in industrial and consumer electronics fields. We not only provide standard PC sheets, but also offer a full range of PC material solutions tailored to customer needs, from custom colors and functional coatings to thin film forms, meeting various design requirements from structural support to surface optical functions.

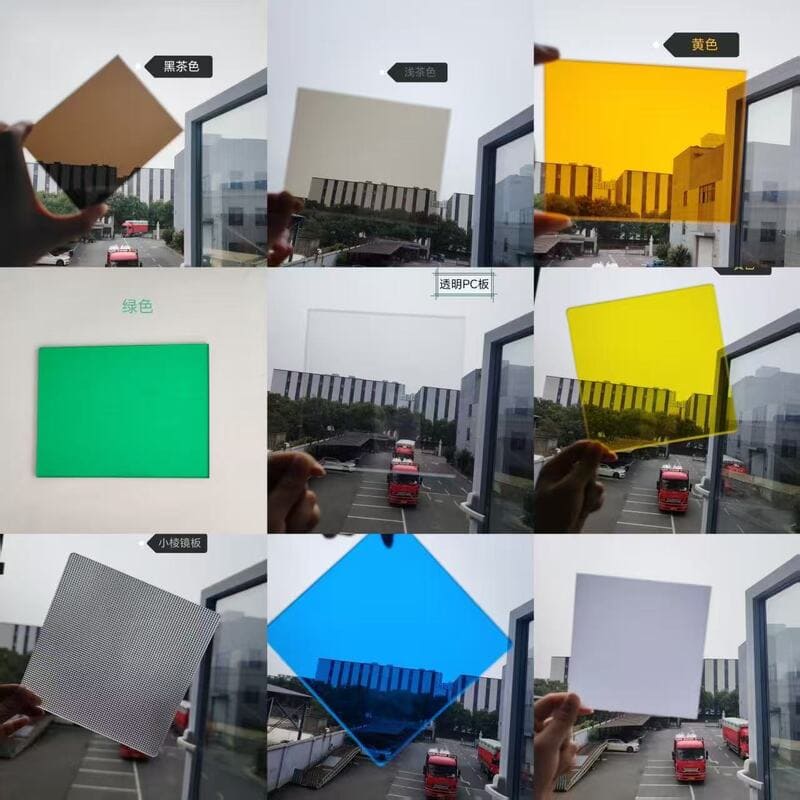

Infuse vibrancy and personality into your products without compromising the inherent superior performance of polycarbonate. Our colored PC sheets are ideal for applications requiring brand identification, status indication, or aesthetic concealment.

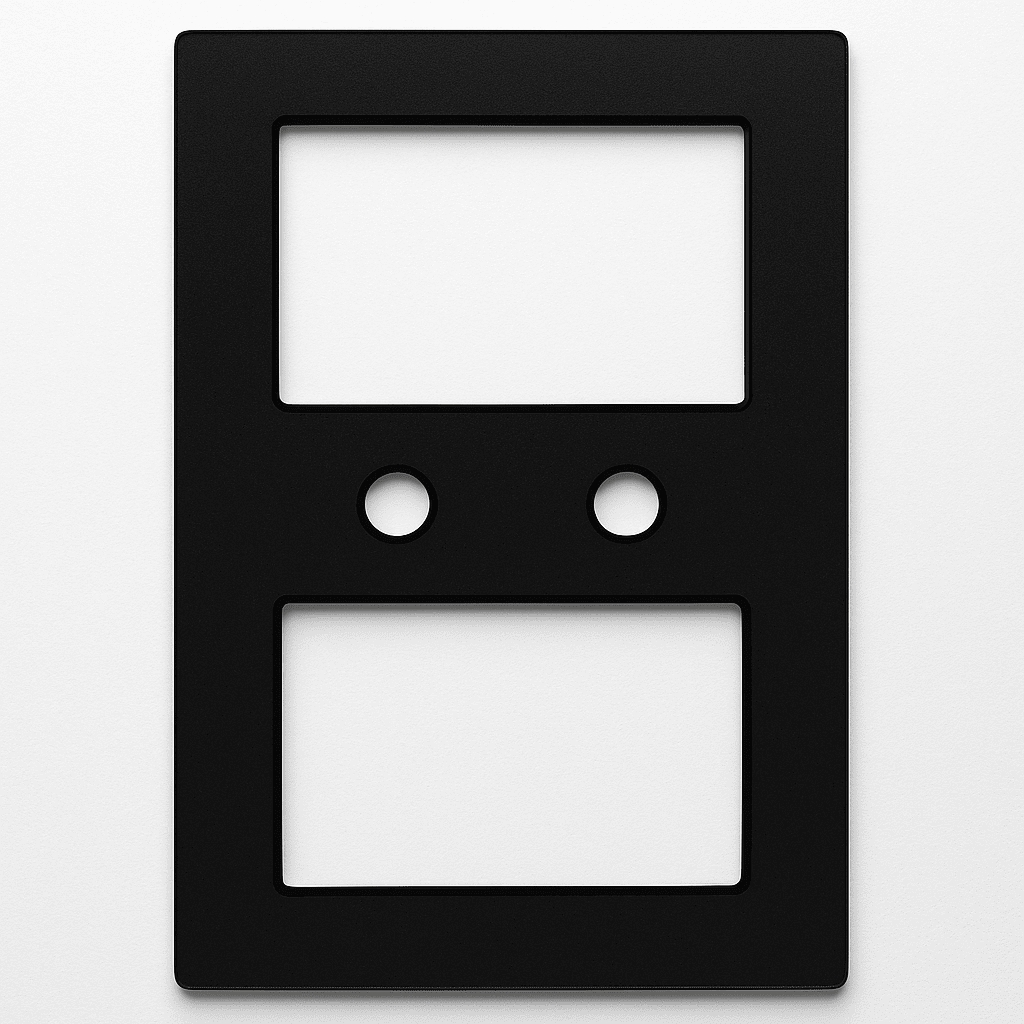

Thickness Range: Available in a wide spectrum from 0.5mm to 10.0mm to accommodate diverse needs – from lightweight decorative components to robust structural parts.

Standard Dimensions: Conventional sheet size: 1220mm x 2440mm. Custom CNC precision cutting available per customer drawings to achieve any shape or dimension.

Coloring Techniques:

Key Properties:

High Light Transmittance & Uniform Hue: Maintains exceptional light diffusion even in dark tones, perfect for indicator covers, lightbox panels, etc.

Outstanding Impact Resistance: Retains PC’s signature strength – dozens of times more shatter-resistant than glass and multiple times tougher than acrylic.

Excellent Heat Resistance: High heat deflection temperature ensures reliability across broad operating environments.

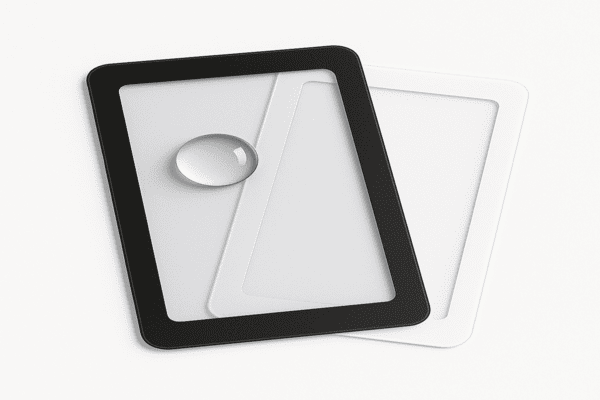

We integrate multiple functionalities (e.g., anti-glare + hard coat + anti-fingerprint) onto a single PC sheet to meet your exact requirements.

All coatings are applied in Class 1,000 cleanrooms to eliminate particulate defects. Adhesion and performance are rigorously validated via:

* Cross-cut testing (ISO 2409)

* Abrasion resistance (ASTM D1044)

* Environmental stress testing (thermal cycling, humidity exposure)

Anti-Scratch / Hard Coat

Performance: Dramatically improving scratch resistance and extending product lifespan while maintaining optical clarity.

Thickness: 3-10μm coating preserves dimensional accuracy of substrate.

Anti-Fog Coat

Performance: Hydrophilic coating prevents condensation-induced fogging, critical for refrigeration units, outdoor equipment, and environments with rapid temperature/humidity shifts.

Anti-Static Coat

Performance: Surface resistivity tuned to 10⁶–10⁹ Ω/sq to mitigate dust adhesion from static buildup, protecting sensitive electronics.

Anti-Reflection / Anti-Glare Coat

Performance: Multilayer deposition or micro-textured surfaces reduce reflectivity and glare, ensuring readability in high-ambient-light environments.

Options: Available standalone or combined with hard coat (AR+Hard Coat) for unified functionality.

Anti-Fingerprint / Oleophobic Coat

Performance: Hydrophobic/oleophobic properties repel fingerprints and oils, enabling effortless cleaning while maintaining aesthetic integrity.

Custom Hybrid Coating Systems

We integrate multiple functionalities (e.g., anti-glare + hard coat + anti-fingerprint) onto a single PC sheet to meet your exact requirements.

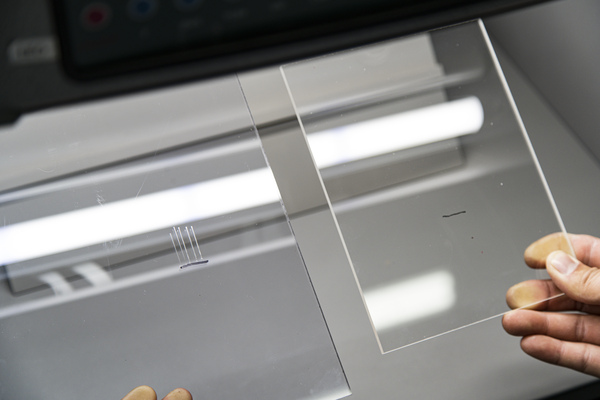

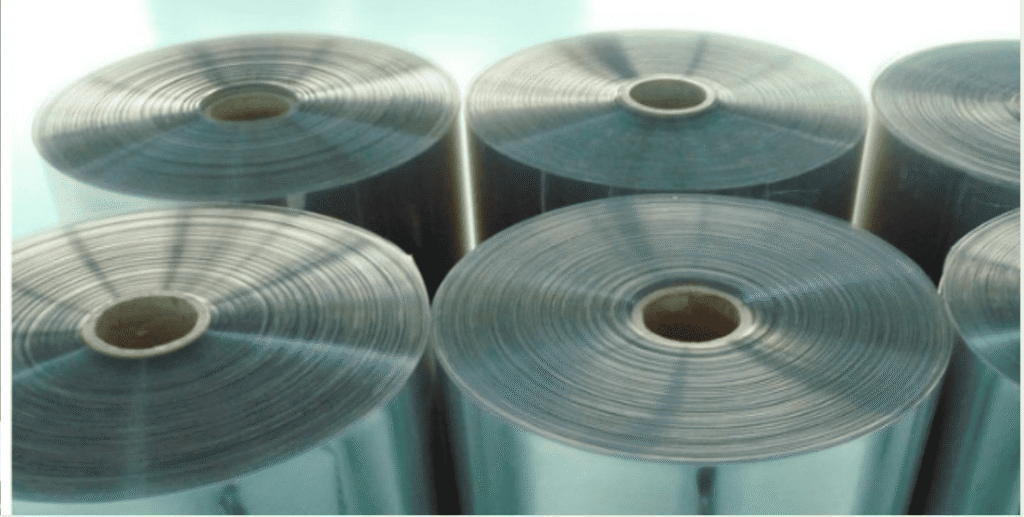

A high-performance solution for lightweight, flexible, or post-processing composite designs—combining dimensional stability, electrical insulation, and superior optical properties

Thickness Range:

0.1mm (100μm) to 0.5mm (500μm), from ultra-thin to standard options.

Formats & Dimensions:

Roll Stock: Standard 930mm wide( can be customized), ideal for continuous roll-to-roll printing, lamination, or die-cutting.

Sheets: Custom-cut to specified sizes upon request.

Key Features:

High Clarity & Low Birefringence: Optimal for display or touch-sensitive layers requiring premium optical quality.

Exceptional Impact & Tear Resistance: Outstanding performance among thin-film materials.

Thermal Stability & Flame Retardancy: Complies with multiple electrical safety standards.

Ease of Secondary Processing: Compatible with printing, coating, laminating, and thermoforming (e.g., IMD/IMF processes).

Functional Enhancements:

Pre-coated options: Hardened, anti-glare (AG), or anti-reflective (AR) surfaces.

IMD (In-Mold Decoration) Films: Compatible with our injection molding for seamless

Consult VIIST today—let our polycarbonate solutions become the foundation for your next-generation products: durable, aesthetically refined, and functionally superior optical covers.