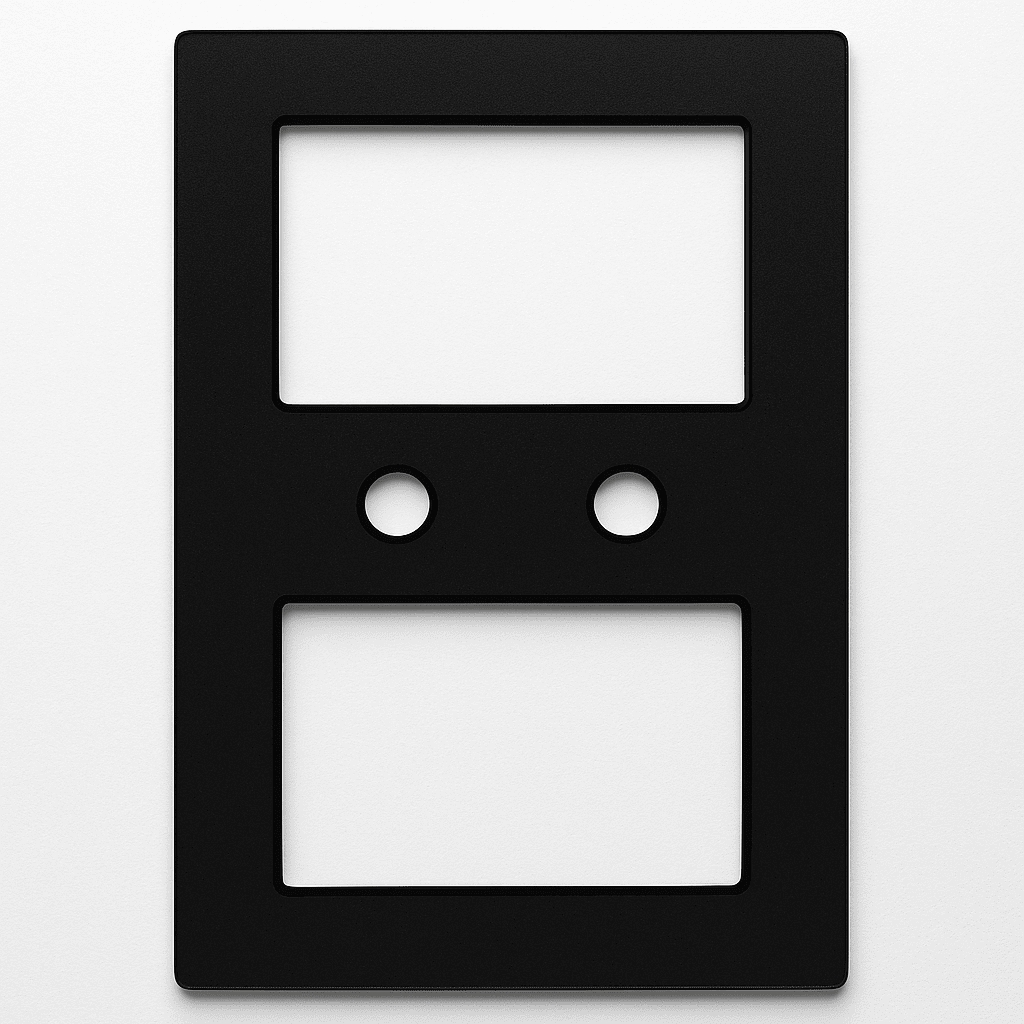

VIIST is a specialized silk screen printing manufacturer providing high-precision printing services for plastic components across various industries. We partner with medical device manufacturers, automotive suppliers, electronics companies, and consumer product brands to deliver exceptional printing quality on multiple substrates.

Our advanced silk printing capabilities ensure:

Process Advantages:

Versatile application on flat, curved, and irregular surfaces

Thick ink deposition for enhanced durability

Excellent opacity even on dark substrates

Cost-effective for medium to high volume production

Wide material compatibility with various plastics

Material Expertise:

Polycarbonate (PC): Impact-resistant, optical clarity

Acrylic (PMMA): Excellent transparency, UV stability

ABS: Good mechanical strength, cost-effective

PETG: Chemical resistance, formability

Polypropylene: Chemical resistance, flexibility

1. Advanced Printing Equipment

Automatic screen printing machines: 6-color, 4-station

UV curing systems: Instant curing with superior adhesion

Infrared drying tunnels: Efficient solvent evaporation

Registration systems: ±0.1mm precision alignment

Cleanroom printing: Class 1000 environment for optical parts

2. Technical Specifications

| Parameter | Capability | Tolerance |

| Maximum Print Size | 500mm × 500mm | ±0.1mm |

| Color Registration | 6 colors | ±0.1mm |

| Ink Thickness | 10-50μm | ±5μm |

| Minimum Line Width | 0.15mm | Consistent |

| Production Speed | Up to 1200 cycles/hour | Consistent |

3. Ink Technology Expertise

UV-curable inks: Instant curing, chemical resistance

Solvent-based inks: Excellent adhesion, flexibility

Thermoplastic inks: Heat resistance, durability

Conductive inks: EMI shielding, circuit printing

Specialty inks: Glow-in-dark, color-changing

4. Surface Treatment Integration

Pre-printing treatment: Plasma activation for improved adhesion

Post-printing hardening: UV curing for scratch resistance

Combined coatings: Printing + functional coating integration

Quality verification: Adhesion testing and durability verification

1. Design & Preparation

Artwork preparation and color separation

Screen selection based on design requirements

Screen coating with appropriate emulsion

Exposure and development for pattern transfer

2. Printing Setup

Substrate preparation and cleaning

Fixture development for precise registration

Ink preparation and viscosity adjustment

Machine setup and parameter optimization

3. Printing Execution

Automatic printing with precise registration

Quality inspection during production run

Curing process optimization

In-process cleaning and maintenance

4. Post-Printing Processing

Curing completion and adhesion verification

Additional coating application if required

Final inspection and quality approval

Packaging and shipment preparation

1. Printing Excellence

20+ years of screen printing experience

ISO 9001:2015 certified quality system

Class 1000 cleanroom for optical components

Automated production with 24/7 operation capability

2. Technical Expertise

Ink formulation expertise for specific material compatibility

Screen making capability in-house for quick turnaround

Color matching technology for brand consistency

Process validation for critical applications

3. Quality Assurance

First article inspection for every new design

In-process quality checks during production

Adhesion testing (cross-hatch ASTM D3359)

Environmental testing (temperature, humidity, chemical resistance)