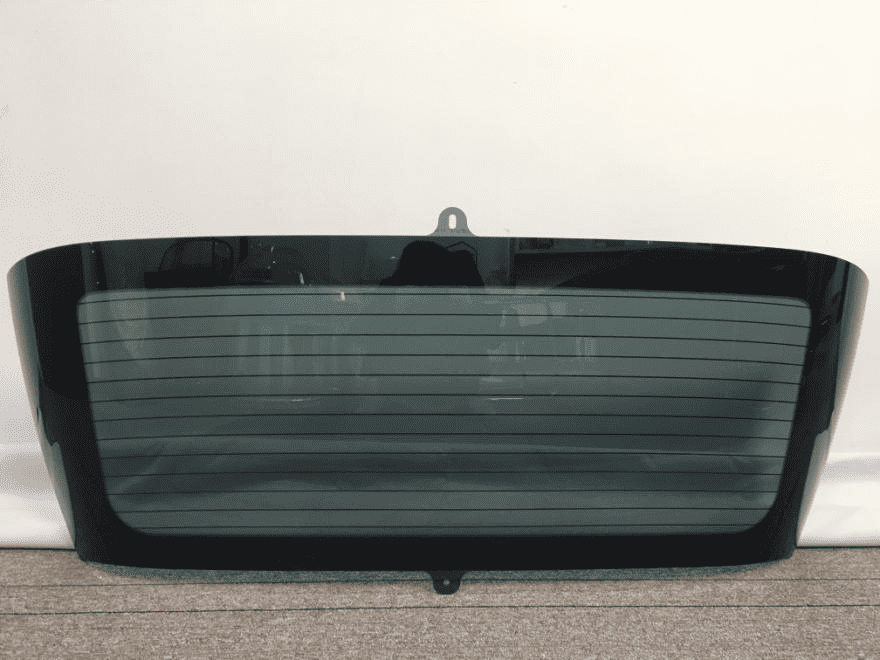

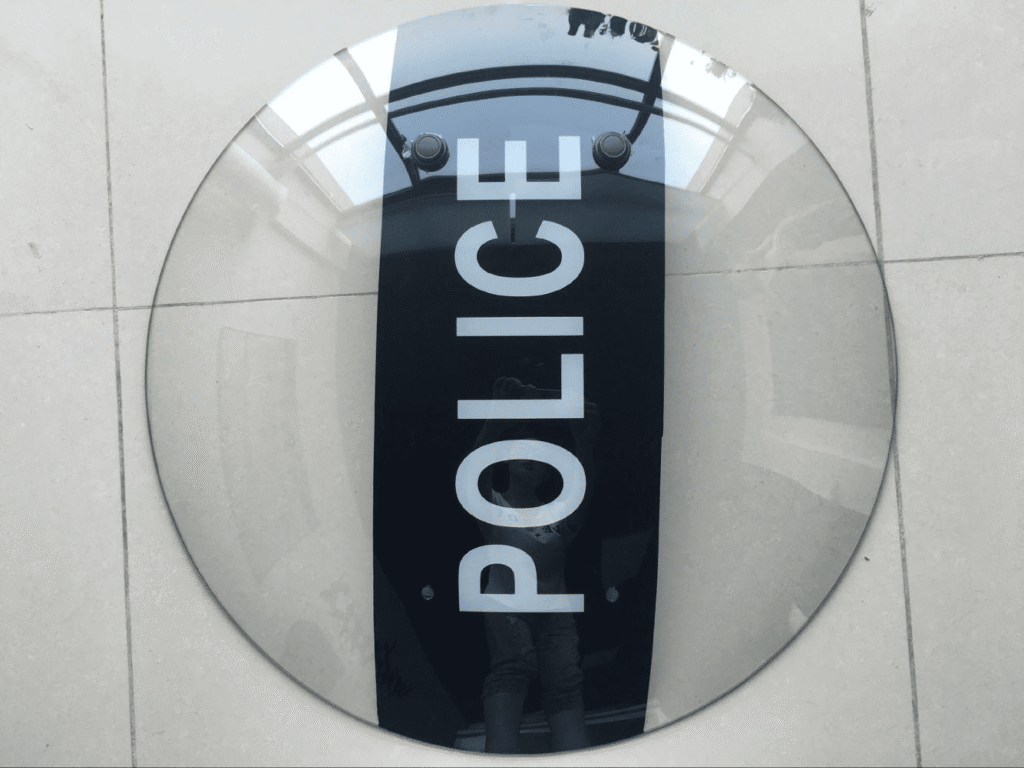

VIIST is a specialized thermoforming and hot bending manufacturer focusing on precision plastic forming for optical, medical, and industrial applications. We partner with leading brands in automotive, electronics, medical devices, and consumer products to create complex-shaped components with exceptional accuracy and surface quality.

Our advanced thermoforming capabilities deliver:

Why Choose Thermoforming & Hot Bending?

Process Advantages:

Cost-effective for medium to high volume production

Large part capabilities beyond injection molding limits

Low tooling costs compared to injection molding

Material versatility across various plastic types

Rapid prototyping and short lead times

Material Expertise:

Polycarbonate (PC): Impact resistance, optical clarity

Acrylic (PMMA): Excellent transparency, UV stability

ABS: Good formability, mechanical strength

HDPE: Chemical resistance, flexibility

PVC: Versatility, cost-effectiveness

PETG: Clarity, formability, chemical resistance

Our Thermoforming & Hot Bending Capabilities

1. Advanced Equipment Portfolio

Hot Bending Machines: Precision computer-controlled forming

Vacuum Forming Presses: Up to 2.5m × 1.5m bed size

Pressure Forming Systems: Enhanced detail resolution

Oven Heating Systems: Precise temperature control (±2°C)

Automated Handling: Robotic part manipulation

2. Technical Specifications

| Parameter | Capability | Tolerance |

| Maximum Part Size | 2500mm × 1500mm | ±0.5mm |

| Material Thickness | 0.5mm – 12mm | ±0.1mm |

| Forming Temperature | 150°C – 200°C | ±2°C |

| Draw Depth | Up to 600mm | ±0.3mm |

| Cycle Time | 2-5 minutes | Consistent |

3. Surface Treatment Expertise

ANTI-scratch: Hard Coating

Anti-Fog Treatment: Permanent hydrophilic coatings

Anti-Glare (AG): Surface etching for optical diffusion

Anti-Reflective (AR): Multi-layer optical coatings

Anti-Fingerprint (AF): Oleophobic nano-coatings

UV Protection: Coatings for outdoor applications

1. Design & Engineering

3D model analysis for formability assessment

Mold design optimized for material distribution

Process simulation for quality prediction

2. Material Preparation

Sheet cutting to precise dimensions

Pre-drying to remove moisture content

Temperature profiling for specific materials

3. Heating & Forming

Even heating for consistent material temperature

Precise timing for optimal forming window

Pressure/vacuum control for detail reproduction

4. Finishing & Assembly

CNC trimming to final dimensions

Edge finishing and polishing

Secondary operations (drilling, tapping)

Surface treatment application

Free design consultation and DFM analysis

Material selection guidance for your application

Prototype services with 5-7 day turnaround

Mass production capacity: 50,000+ units monthly

Complete supply chain management

Contact our thermoforming experts today