The Ultimate Guide to Display Cover Glass: Materials, Applications & Benefits

A Display Cover Glass is a protective outer layer installed over electronic displays, such as those on smartphones, tablets, monitors, and automotive dashboards. It serves as the first line of defense against physical damage, environmental factors, and wear while ensuring optimal visibility and touch sensitivity.

In this blog, you will discover everything about display front panels, including materials like acrylic, polycarbonate, and PC-PMMA composite, functional coatings, and applications in touchscreens. Learn how to choose the best solution for your project.

Table of Contents

- What is a Display Front Panel?

- Key Materials for Display Coverlens

- Acrylic (PMMA)

- Polycarbonate (PC)

- PC-PMMA Composite

- Glass

3.Manufacturing Processes for Display Cover Panels

4.Applications of Protective Front Panels

5.Why Choose Excelite Plas for Your Screen Front Panels?

1. What is a Display Front Panel?

A display front panel (also called a cover lens, protective front panel) is the outermost layer of an electronic device’s interface. It serves with some key functions:

Physical Protection

- Shields the underlying display (LCD, OLED, etc.) from scratches, impacts, and cracks.

- Commonly made from tempered glass (e.g., Gorilla Glass), polycarbonate (PC), Acrylic(PMMA) or sapphire crystal for enhanced durability.

Optical Clarity

- Designed with anti-reflective coatings to reduce glare and improve readability under bright light.

- Maintains high light transmission (>90%) for vibrant visuals.

Touch Sensitivity

- Enables smooth touch interaction (for capacitive touchscreens).

- Some panels integrate oleophobic coatings to resist fingerprints and smudges.

Environmental Resistance

- Water and dust resistance (e.g., IP68-rated panels for smartphones).

- UV-resistant coatings to prevent yellowing or degradation over time.

Aesthetic Enhancement

- Provides a sleek, seamless surface (e.g., edge-to-edge designs for modern devices).

- Customizable with silk printing, matte finishes, or privacy filters.

Structural Support

Reinforces the display assembly, preventing flex or damage to internal components.

Due the above functionals, the protective cover lens with a widely applications in industrial control panels, medical devices, consumer electronic( smartphone, tablets, kiosks), automotive dashboards and home automation systme etyc.

2.Key Materials for Display Front Panels

The choice of material for a display protective panel depends on some factors like durability, optical clarity, cost, and application requirements. Below is a detailed explanation of why acrylic (PMMA), polycarbonate (PC), glass, and PC-PMMA composites are commonly used.

1)Acrylic (PMMA) – Polymethyl Methacrylate

Why Use It?

- High Optical Clarity (92% light transmission) – Minimal distortion, ideal for displays requiring bright, clear visuals.

- Lightweight & Cost-Effective – Cheaper than glass and polycarbonate, suitable for budget devices.

- Good Scratch Resistance – Harder than PC, but not as scratch-resistant as glass.

- Easier to Fabricate – Can be laser-cut, thermoformed, and polished easily.

Drawbacks

Brittle – Prone to cracking under impact (unlike flexible PC).

Lower Chemical Resistance – Can degrade with solvents or UV exposure over time.

Typical Applications

So for some Low-cost touchscreens (e.g., kiosks, industrial displays), and some ecorative panels where extreme durability isn’t critical, the PMMA cover lens will be a good choice for you.

2)Why choose olycarbonate (PC) material

Some typicl pros as berlow,

- Extremely Impact-Resistant – Virtually unbreakable, ideal for rugged devices.

- Lightweight & Flexible – Can bend without cracking (unlike glass or PMMA).

- Good Thermal Stability – Withstands high temperatures better than PMMA.

- Can Be Chemically Hardened – With coatings (e.g., anti-scratch coating/hard coating) to improve scratch resistance.

Drawbacks

Poor Scratch Resistance – Softer than glass/PMMA, requires hard coatings.

Lower Optical Clarity (88-90% transmission) – Slight haze compared to glass.

Higher Cost Than PMMA – But still cheaper than advanced glass.

Typical Applications

Due to the high impatc resistance of PC sheet, the PC front panel normally applied in Military, aviation, and automotive displays (where shatterproofing is critical). Also the children’s tablets, industrial equipment, and wearable devices.

3)Glass (Chemically Strengthened/Tempered)

Glass often used display protect cover panel mainly depending one below features:

- Best Scratch Resistance – Hardness close to sapphire (e.g., Gorilla Glass).

- Premium Feel & Clarity (≥90% transmission) – Ideal for high-end smartphones.

- Can Be Chemically Treated – Oleophobic coatings reduce fingerprints.

- Excellent Environmental Resistance – Resists UV, moisture, and chemicals.

But glass also with some limits:

Brittle – Can shatter upon impact (though tempered glass is stronger).

Heavy – Adds weight compared to plastics.

Expensive – Especially with advanced coatings (e.g., anti-reflective).

Typical Applications

Smartphones (e.g., iPhone, Samsung Galaxy).

High-end tablets, smartwatches, and automotive displays.

4) PC-PMMA Composite (Hybrid Material)

The composit sheet combines Strengths of PC & PMMA:

- PMMA outer layer → Provides hardness & scratch resistance.

- PC inner layer → Adds flexibility & impact resistance.

- Better Optical Quality Than Pure PC – Closer to glass clarity.

- Lightweight & Cost-Effective – Cheaper than pure glass solutions.

The PC-PMMA sheet typical applied on mid-range smartphones(e.g., some Huawei, Xiaomi models). And automotive touchscreens where a balance of cost and durability is needed. Normally, it still requires hard coatings, as the hardness itself not as scratch-resistant as glass, often combioned with other functional coatings like anti-glare coating/anti-fingerprinting coating etc

You can also have a brief understanding for differnt material pros and cons from the below comparison table.

| Material | Impact Resistance | Scratch Resistance | Optical Clarity | Weight | Cost |

| PMMA | Low | Medium | High | Light | Low |

| PC | Very High | Low (needs coating) | Medium | Light | Medium |

| Glass | Low (but tempered helps) | Very High | Very High | Heavy | High |

| PC-PMMA | High | Medium-High | High | Light | Medium |

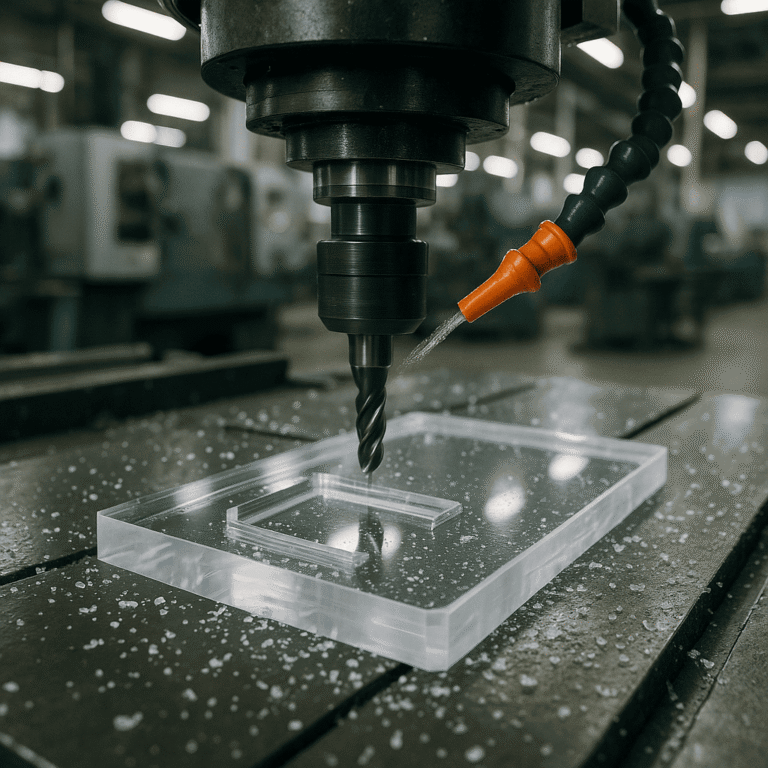

3. Manufacturing Processes for Display Cover Panels

The production of display cover lens involves several critical processes to ensure optical clarity, durability, and functionality.

Material Cutting (Laser/CNC)

Edge Polishing

Cleaning (Ultrasonic/Plasma)

Silk Screen Printing (Logos, borders, masking)

Curing (UV/Heat)

Functional Coatings (AR, oleophobic, etc.)

Final Assembly.

A well-designed display front panel enhances both functionality and aesthetics. Whether you need scratch-resistant acrylic, ultra-tough polycarbonate, or sleek glass, the right material and coating can make all the difference.

For custom front panels, trust VIIST optical – your partner in high-performance display solutions!

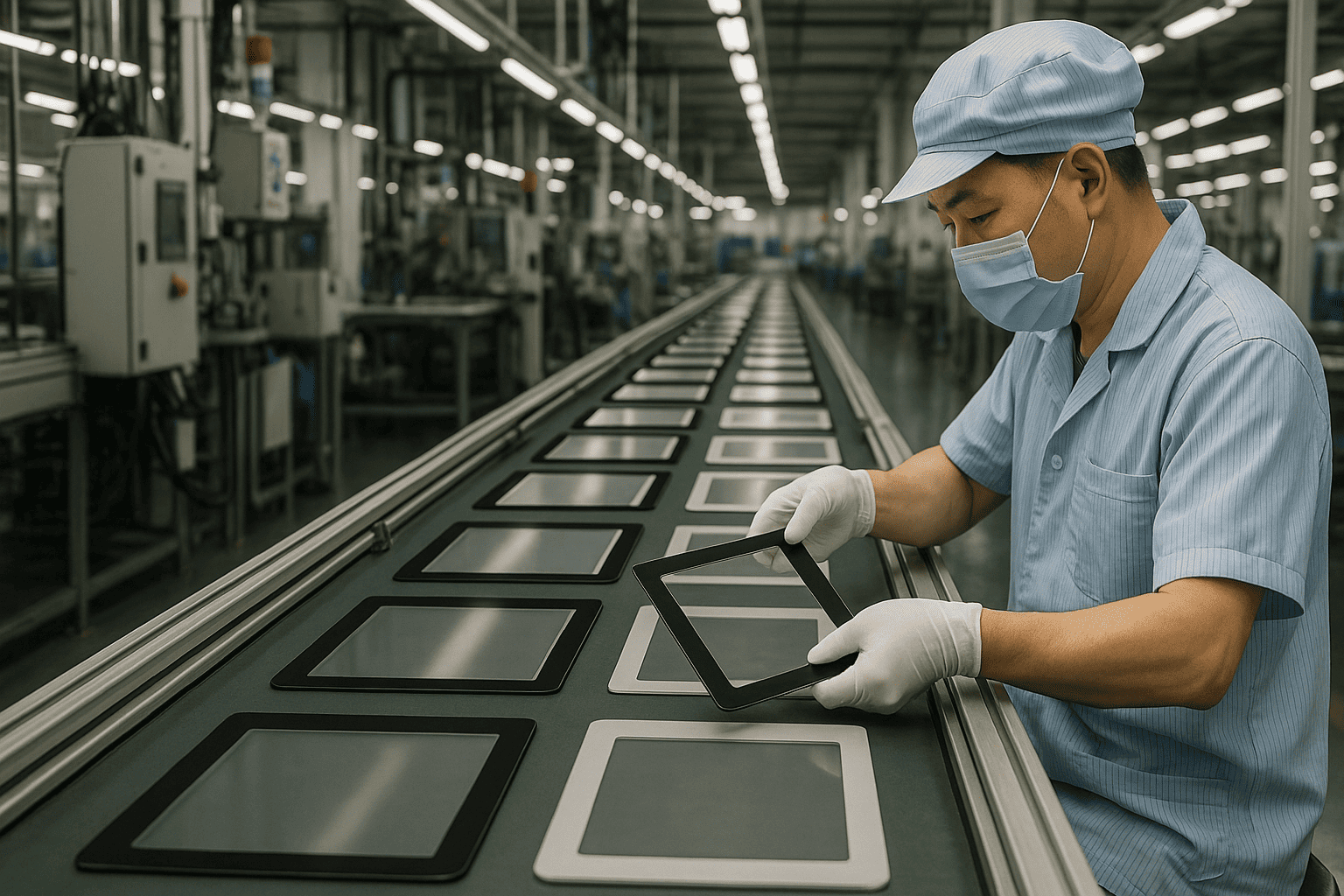

4. Applications of Display Front Panels

- Industrial Control Panels – Requires impact-resistant PC or PC-PMMA with anti-glare coatings.

- Medical Devices – Needs easy-to-clean glass or PMMA with antimicrobial coatings/anti-fingerprinting coating.

- Consumer Electronics – Uses glass or PC-PMMA for sleek designs.

- Automotive Displays – Requires heat-resistant, anti-reflective coated panels.

5. Why Choose VIIST Optical?

VIIST offers comprehensive manufacturing solutions for front panels, backed by:

Full In-House Capabilities: Equipped with advanced machinery for end-to-end production.

Expert Engineering Team: 10+ years of experience in front panel design and manufacturing.

Tailored Services: From raw material selection to prototyping, we provide customized solutions to meet your exact requirements.

Our specialists are ready to:

✅ Analyze your project needs

✅ Propose optimized cover lens designs

✅ Deliver precision-manufactured components

Let’s discuss how we can support your project. Contact us today to get started!